Hydraulic press for locks QUANTUM NARGESA PI85, with a fast and accurate perforation for the casing, handle and lock hole in a tube. It's a state-of-the-art novelty in the world of locks. Patented by Nargesa in 2006, this machine makes us the leaders in the manufacturing of this kind of machine.They fit 85% of locks of all trademarks and models.

PI85: Hydraulic Press for Locks (Lock Press)

WATCH THE VIDEO TO SEE EXACTLY HOW THE NARGESA PI85 LOCK PRESS WORKS ALONG WITH SOME OF IT’S FEATURES

-

Normally, one operative has an average time between 30 - 45 minutes to make one whole operation for a casing, handle holes and the lock hole in a square or rectangular tube. With the PI85 Nargesa the time gets reduced to less than one minute. This is a machine for high production. The finish is perfect, with the proper tolerance to place the lock with no need to use a bezel. Thus the assembling time is minimum. Many companies that have bought this press for locks PI85, not only for their own use but also to sell the ready-to-be-used tubes to other companies. It's important to bear in mind the casing must be always made in the side of 1.37”, 1.57” or 1.96” (35, 40 or 50mm). The perforation of the lock hole and the handle could be combined, it means we can punch a tube with lock and handle on both ends, as we can as well make either the handle or the lock in the other.

TECHNICAL SPECS AND FEATURES

-

- Distance Between Axis: 3.34” (85mm)Type of Keyhold: Bombin

- Operation Time: Approx. 58 Seconds

- Engine Power: 1 HP (0.75 kw)

- Approx. Machine Weight: 440 lbs. (200 kg.)

- Machine Dimensions: 59" x 23" x 58"

- Height of the PI85: 58” (1,470mm)

- Width of the PI85: 59” (1,500mm)

- Length of the PI85: 22.4” (570mm)

- The square and rectangular tubes that can be used with the machine are (in inches): 1.37”x1.37”, 1.57”x1.57”, 1.57”x1.96”, 1.57”x2.36”, 1.57”x2.75”, 1.57”x3.15”, 1.96”x1.96”, 1.96”x2.36”, 1.96”x2.75” and 1.96”x3.15”.

- The square and rectangular tubes that can be used with the machine are (in mm): 35x35, 40x40, 40x50, 40x60, 40x70, 40x80, 50x50, 50x60, 50x70 and 50x80.

- The Hydraulic Press for Locks Nargesa allows making different kinds of punching operations:

- Punching for mechanism entrance, the lock and handle to both sides.

- Punching for mechanism entrance, the lock and handle in only one side.

- Punching for mechanism entrance, the lock with no handle.

- Tube thickness can be 0.060” (1.5mm) and 0.080” (2mm). No matter the material, it can either punch normal steel, galvanized steel or stainless steel.

- The casing length is adjustable as it is as well the entrance of the lock. It ranges from 0.70” (18mm) to 1.45” (37mm).

- Normally, one operative has an average time between 30 - 45 minutes to make one whole operation for a casing, handle holes and the lock hole in a square or rectangular tube. With the PI85 Nargesa the time gets reduced to less than one minute. This is a machine for high production.

- The finish is perfect, with the proper tolerance to place the lock with no need to use a bezel. Thus the assembling time is

-

- minimum.

- Many companies that have bought this press for locks PI85, not only for their own use but also to sell the ready-to-be-used tubes to other companies.

- It's important to bear in mind the casing must be always made in the side of 1.37”, 1.57” or 1.96” (35, 40 or 50mm).

- The perforation of the lock hole and the handle could be combined, it means we can punch a tube with lock and handle on both ends, as we can as well make either the handle or the lock in the other.

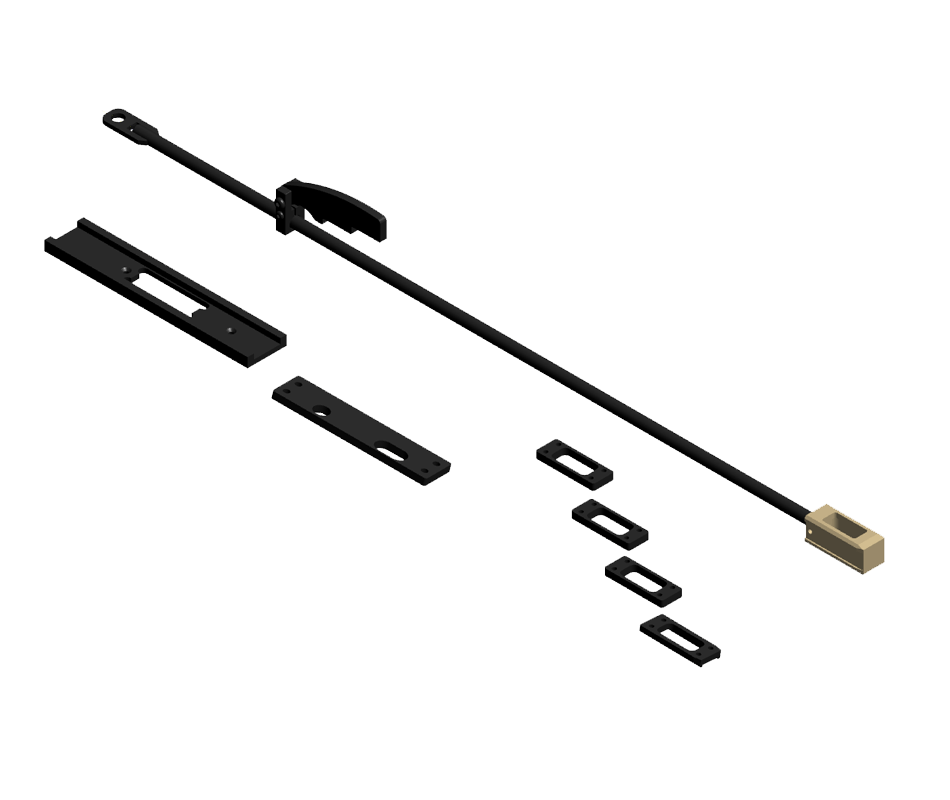

OPTIONAL ACCESSORIES

(REF: 140-07-01-00001)Square Tube: 1.37”x1.37” (35x35mm)

Max. Tube Thickness: 0.060” (1.5mm)

Pieces Per Tool Set: 3 Units

(Accessory Weight: 11 lbs.)

(REF: 140-07-01-00003)Square Tube: 1.57”x1.57” (40x40mm)

Rectangular Tube (inches): 1.57”x1.96”, 1.57”x2.36”, 1.57”x2.75”, 1.57”x3.15”

Rectangular Tube (mm): 40x50mm, 40x60mm, 40x70mm, 40x80mm

Max. Tube Thickness: 0.060” (1.5mm)

Pieces Per Tool Set: 8 Units

(Accessory Weight: 12 lbs.)

(REF: 140-07-01-00004)Square Tube: 1.57”x1.57” (40x40mm)

Rectangular Tube (inches): 1.57”x1.96”, 1.57”x2.36”, 1.57”x2.75”, 1.57”x3.15”

Rectangular Tube (mm): 40x50mm, 40x60mm, 40x70mm, 40x80mm

Max. Tube Thickness: 0.080” (2mm)

Pieces Per Tool Set: 8 Units

(Accessory Weight: 12 lbs.)

(REF: 140-07-01-00005)Square Tube: 1.96”x1.96” (50x50mm)

Rectangular Tube (inches): 1.96”x2.36”, 1.96”x2.75”, 1.96”x3.15”

Rectangular Tube (mm): 40x60mm, 40x70mm, 40x80mm

Max. Tube Thickness: 0.060” (1.5mm)

Pieces Per Tool Set: 7 Units

(Accessory Weight: 12 lbs.)

(REF: 140-07-01-00006)Square Tube: 1.96”x1.96” (50x50mm)

Rectangular Tube (inches): 1.96”x2.36”, 1.96”x2.75”, 1.96”x3.15”

Rectangular Tube (mm): 40x60mm, 40x70mm, 40x80mm

Max. Tube Thickness: 0.080” (2mm)

Pieces Per Tool Set: 7 Units

(Accessory Weight: 12 lbs.)