The End Hot Wrought Machine Nargesa PC16, eases up the rolling job of hot steel. It rolls up the snail forged shaped end. This decorations are commonly used as extremes in scrolls and decorative parts. Gates, windows, fencing, metal furniture, etc...

PC16: Industrial End-Wrought Iron Machine

EXTREMELY FAST SHIPPING

All In-Stock Orders are Now Shipping Out in Just 1 to 3 Business Days

PC16: Industrial End-Wrought Iron Machine

Sale price$11,550

WATCH THE VIDEO TO SEE EXACTLY HOW THE NARGESA PC16 END WROUGHT IRON MACHINE WORKS ALONG WITH SOME OF IT’S FEATURES

ADVANTAGES

- Easy Handling: Any worker is able to carry out this job, even without any previous preparation.

- Readiness: Thousands of parts can be made in one working day.

- Value and Prestige: There are few craftsmen who can make these kinds of wrought jobs.

- Sales: Possibility of selling parts with the forged extremes to different companies or steel stores.

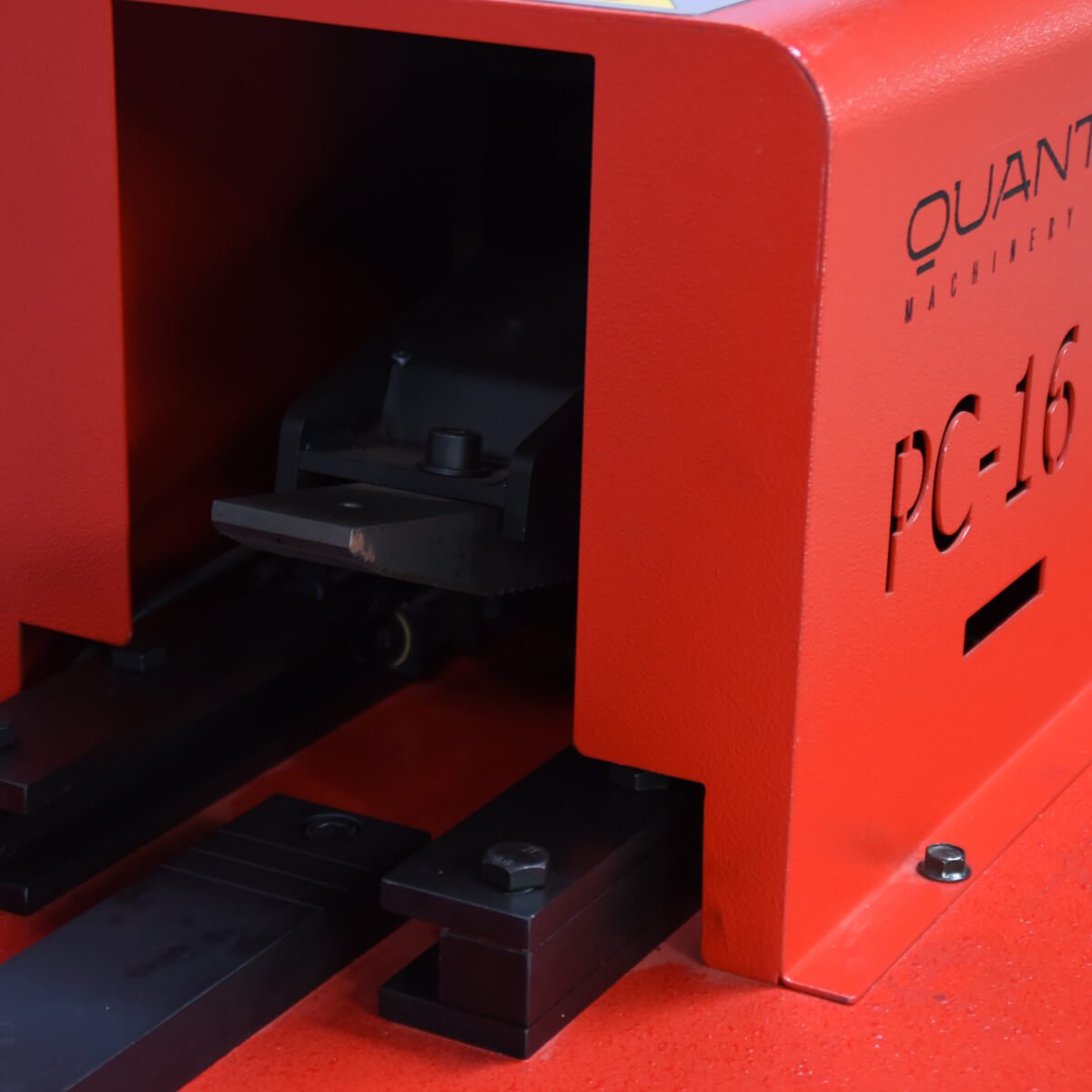

- The End Hot Wrought Machine Nargesa PC16, makes snails shaped extremes in round bar, square bar and flat bars of different sizes...

- 3-Year Defective Parts Warranty: Nargesa machines have 3-year warranty, provided that the customer registers it in the Nargesa website upon arrival. Otherwise it would be only one year warranty. Enclosing any manufacturing default all along these 3 years for components. Any misuse is excluded from this condition. Labor, back and forth shipping and any eventual repair, are not included in this warranty.

TECHNICAL SPECS AND FEATURES

- Max. Round Capacity: 0.78” (20mm)

- Max. Square Capacity: 0.78” (20mm)

- Max. Flat Bar Capacity: 1.9”x0.39” (50x10mm)

- Working Speed: 1.77”/s (45mm/s)

- Return Speed: 2.75”/s (70mm/s)

- Cycle Time: 10 seconds

- Pieces per Minute: 4 pieces.

- Engine Power: 3 HP / 2.2 kw

- Dimensions: 50” x 25” x 43”

- Machine Weight: 685 lbs.

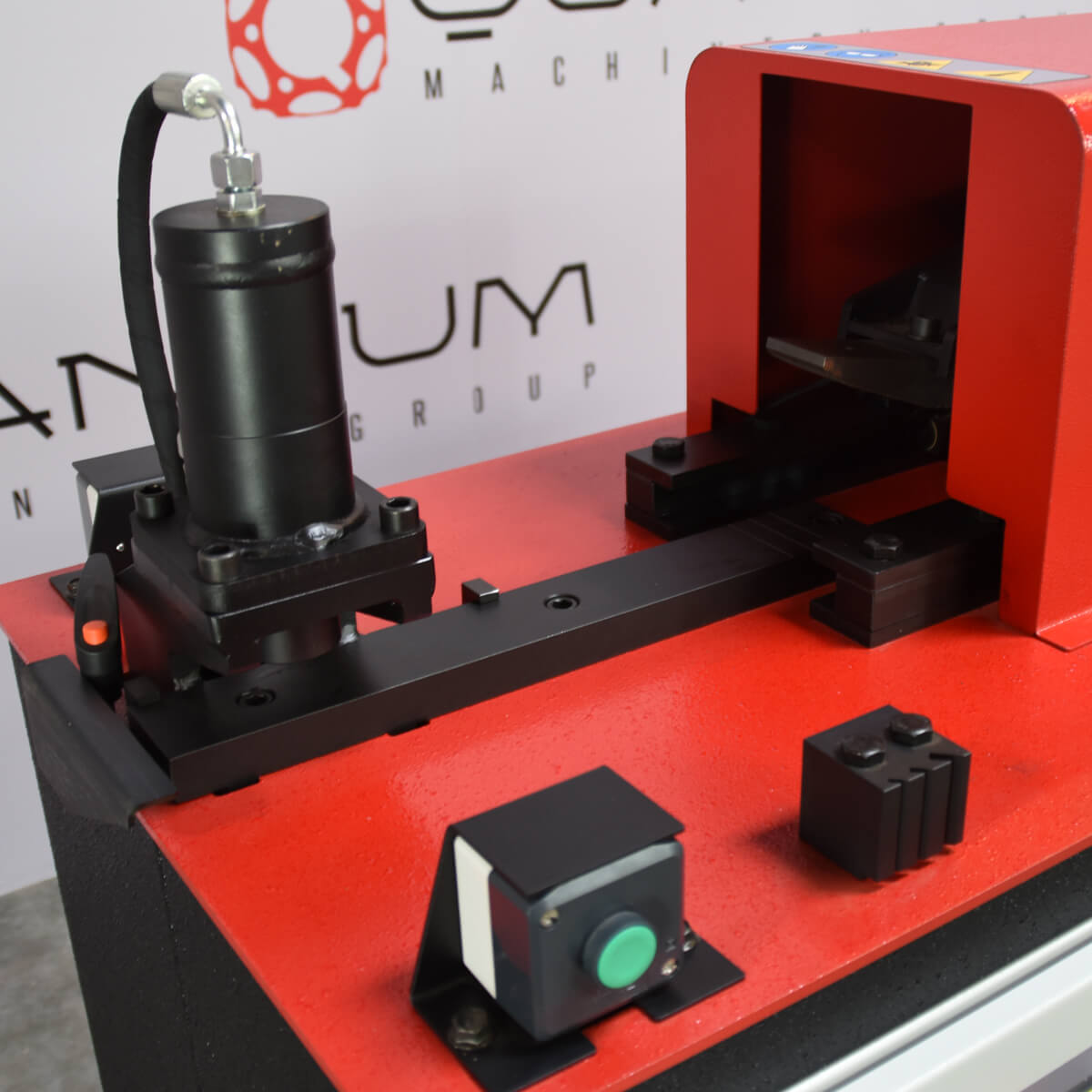

- Adjustment of displacement or turns.

- Adjustment of pressure according to material thickness.

- Safety double command for the cycle drive.

- Hydraulic clamp for the piece fastening.

- Easy Handling: Any worker is able to carry out this job, even without any previous preparation.

- Readiness: Thousands of parts can be made in one working day.

- Value and Prestige: There are few craftsmen who can make these kinds of wrought jobs.

- Sales: Possibility of selling parts with the forged extremes to different companies or steel stores.

- The End Hot Wrought Machine Nargesa PC16, makes snails shaped extremes in round bar, square bar and flat bars of different sizes...

- Hot Steel Temperature: In order to be able to accomplish these hot steel applications, it is very important to have the piece at a proper heated temperature. Our Nargesa Propane Gas Forging Furnaces H1 (Single Burner), H2 (Dual Burner) and the H3 (Triple Burner) are the best, cleanest, and safest solutions to reach the high temperatures necessary to “snail the ends”.

- 3-Year Defective Parts Warranty: Nargesa machines have 3-year warranty, provided that the customer registers it in the Nargesa website upon arrival. Otherwise it would be only one year warranty. Enclosing any manufacturing default all along these 3 years for components. Any misuse is excluded from this condition. Labor, back and forth shipping and any eventual repair, are not included in this warranty.